Advanced PET Film Engineering for Touchscreens with Curves and Flexibility

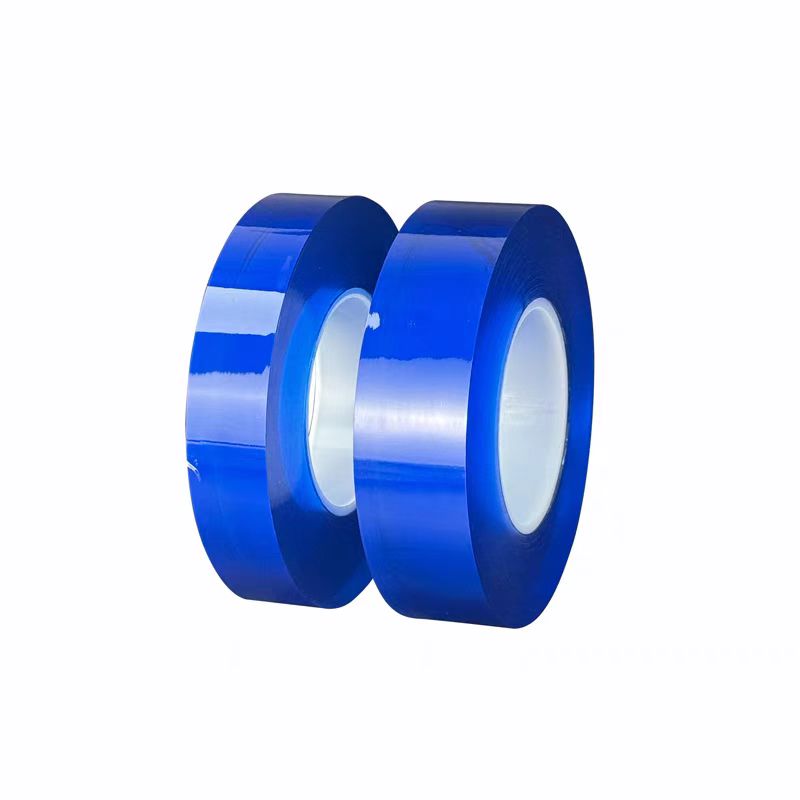

Flexible electronics and interactive displays are reshaping industries—from consumer electronics to automotive and medical devices. A key enabler of these technologies is the flexible PET film, which offers the unique ability to conform to curves and folds while maintaining the electrical and optical properties needed for high-end touchscreens.

1. The Rise of 3D and Foldable Displays

From foldable smartphones to concave dashboard displays, product designers demand more than just durability—they need adaptable and responsive materials. That’s where PET film for touch screen technology comes into play. Its benefits include:

- Thin-film flexibility with surface durability

- Wide compatibility with adhesive and conductive layers

- Stable touch performance under constant bending

These characteristics are essential for displays that move, flex, or wrap.

2. PET for Curved Display Designs

Curved interfaces enhance user experience and design aesthetics. PET for curved display applications must withstand form-fitting processes such as thermoforming, pressure-lamination, or vacuum mounting. Modern PET films are:

- Formulated with improved elongation and anti-curl behavior

- Coated with anti-scratch and anti-reflection layers

- Available in optically clear grades for OLED and LCD overlays

These enhancements help maintain clarity and touch sensitivity on 3D surfaces.

3. Touch Sensitivity in Harsh Environments

Devices used outdoors or in industrial settings must function flawlessly despite environmental stress. Flexible PET film offers benefits such as:

- UV resistance and anti-yellowing properties

- Thermal stability over a wide temperature range

- Low moisture absorption and chemical resistance

All while maintaining the accuracy required in PET film for touch screen systems.

4. PET Film Stack Integration

Flexible PET is often one part of a multi-layer construction. Typical stacks include:

- PET substrate + ITO layer for conductivity

- Hard coating + AF coating for durability and cleanliness

- Adhesive backing compatible with touch sensors or displays

This layered approach allows PET for curved display solutions to meet both mechanical and user interaction requirements.

5. Next-Generation Development

R&D in PET film engineering is expanding to meet the growing needs of flexible displays. Innovations include:

- Stretchable PET-based films for fold-and-roll devices

- Smart PET with embedded sensors or light-diffusing layers

- Recyclable PET film options for sustainable electronics

These advancements will continue to support the adoption of flexible PET film across all sectors.

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.