Extreme Labels: Building PET Solutions for the Harshest Conditions

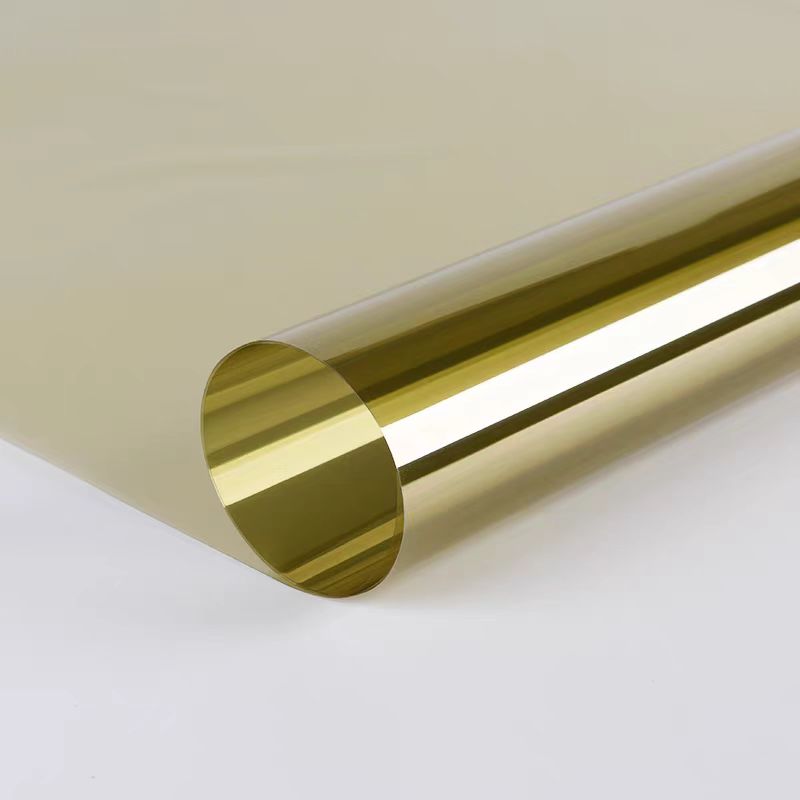

In high-performance industries, labels are more than identification tools—they are survival assets. Whether facing heat, moisture, or mechanical stress, a self-adhesive PET label must provide long-term reliability. This article explains how heat-resistant PET labels, PET label weatherproof systems, and heavy-duty label film compositions endure in extreme environments.

1. Why PET is the Material of Choice

PET film is engineered for resilience. Its properties include:

- Dimensional stability: Doesn’t shrink or curl under heat

- Low moisture absorption: Maintains adhesion in humid environments

- High tensile strength: Resists tearing on curved or textured surfaces

Its balance of flexibility and toughness makes it the go-to choice for heat-resistant PET labels.

2. Surface & Ink Compatibility

PET supports multiple printing technologies:

- Thermal Transfer: Best for barcodes and GHS compliance

- UV Inkjet: Offers vibrant color and durability

- Resin-based Ribbons: Extreme chemical and abrasion resistance

Inks must bond strongly and resist smudging or fading over time.

3. Temperature Tolerance & High-Heat Resistance

- PET labels retain shape and adhesion up to 150°C

- UV topcoats and lamination protect print under thermal cycling

- Adhesives engineered for high heat won’t degrade or ooze

This makes PET the ideal film for electronics, automotive, and appliance labels where heat is constant.

4. Weatherproofing Strategies

Creating a PET label weatherproof requires layered protection:

- UV coatings: Prevent discoloration and brittleness

- Waterproof adhesives: Maintain bond in rain and snow

- Non-porous topcoats: Resist mold, dust, and salt spray

Such PET labels perform flawlessly in agriculture, shipping, and outdoor signage.

5. Enhancing Durability with Laminates

For added strength, PET labels may include laminates that:

- Improve scratch and chemical resistance

- Reduce frictional wear in handling

- Allow cleaning with alcohol, detergents, or solvents

This is key to maintaining a heavy-duty label film in factory or warehouse settings.

6. Adhesive Engineering for Harsh Surfaces

Surfaces like powder-coated metals, plastics, and oily housings require specific adhesives:

- Acrylic (High-Performance): Long-term outdoor use

- Silicone-Based: Thermal cycling and chemical resistance

- Rubber Hybrid: Good tack for curved/rough surfaces

Choosing the right bond layer ensures reliable performance regardless of surface stress.

7. Real-World Applications

| Industry | Challenge | Labeling Solution |

|---|---|---|

| Telecom | Outdoor boxes & solar exposure | PET label weatherproof + UV lamination |

| Industrial | Friction, dust, abrasion | Heavy-duty label film with overlaminate |

| Transport | Under-hood temperatures | Heat-resistant PET label + high-temp adhesive |

8. Regulatory Compliance & Standards

- UL 969: Adhesion and legibility in industrial conditions

- BS5609: Saltwater and chemical durability for marine labels

- RoHS & REACH: Chemical safety for global applications

Labels for mission-critical use must be tested against both performance and environmental metrics.

SEO Keywords

heat-resistant PET label, PET label weatherproof, heavy-duty label film

READ MORE:

Telephone: 008613530419893

E-mail:marie@selfadhesivefilm.com

ADDRESS (Shenzhen):903-286, Building A2, Guangming Technology Park, China Merchants Group, Guanguang Road, Fenghuang Community, Fenghuang Street, Guangming District, Shenzhen, Guangdong.

ADDRESS (Dongguan): 3rd Building No.45 Yinhu Road Shishuikou Community,Qiaotou Town, Dongguan, Guangdong.